Product Description:

A High temperature lab furnace is an essential piece of equipment for various industries that require precise and controlled heating processes. One of the key products in this category is the Ceramic Sintering Furnace, which is a High temperature vacuum sintering furnace designed for efficient sintering of ceramics.

One of the standout features of the Ceramic Sintering Furnace is its impressive cooling time. When the furnace is empty, the cooling time of sintering temperature from 1450 ℃ to 100 ℃ is less than or equal to 2/4/7 hours, ensuring quick and efficient cooling cycles.

Another advantage of this furnace is its long service life, making it a reliable and durable investment for any laboratory or industrial setting. The leakage rate of the furnace is also impressive, with a measurement of ≤3Pa/h when tested in an empty, clean, and cold state.

The Wax collecting rate of 1800Kg ensures that the furnace can handle large quantities of material during the sintering process without any issues. Additionally, the temperature control of the furnace is top-notch, with independent control allowing for precise adjustments. The temperature control is maintained within ≤ ±5 ℃, utilizing the Ferro Brand MTH Temperature Measuring system for accuracy.

For Vacuum Heat - Treating Furnace applications, this Ceramic Sintering Furnace is equipped to handle the rigorous demands of high-temperature sintering processes. The temperature measuring ring provided with the furnace can be placed on the graphite plate for testing at temperatures ranging from 1350-1550°C, ensuring accurate temperature monitoring throughout the sintering cycle.

In conclusion, the Ceramic Sintering Furnace is a versatile and reliable High temperature vacuum sintering furnace that is ideal for various industrial applications. With its efficient cooling time, long service life, low leakage rate, high wax collecting capacity, and precise temperature control, this furnace is a valuable asset for any laboratory or manufacturing facility.

Features:

- Product Name: Ceramic Sintering Furnace

- Wax collecting rate: ≥ 98%(10kg Paraffin Refined Wax , Ar Negative Pressure Dewaxing, Three Averages At Most)

- Effective working zone size: 224/4412/5512/5518

- Working Pressure: 10/20/30/60/100/200 Bar

- Type: Integrated

- Temperature control independently: ≤ ±5 ℃ (using Ferro Brand MTH Temperature Measuring), Provided By The User. Under Vacuum Sintering Conditions, Follow The Processes Listed In The Item 10 Final Acceptance At The Buyer’s Site. The Temperature Measuring Ring Will Be Placed On The Graphite Plate For Testing At 1350-1550°C.

Technical Parameters:

| Items | Technical Parameter |

|---|

| Max. temperature | 2400℃ |

| Temperature Control Mode | 3-zone Temperature Control Independently |

| Wax collecting rate | ≥ 98% (10kg Paraffin Refined Wax, Ar Negative Pressure Dewaxing, Three Averages At Most) |

| Working Pressure | 10/20/30/60/100/200 Bar |

| Leakage rate | ≤3Pa/h (Measuring The Limit Vacuum After Drying The Furnace, Stop The Operation Of The Pump Group And Start The Test. Average Within 3 Hours In Empty Furnace, Clean And Cold State) |

| Max.loading weight | 50/100/150/300/500/1200/1500KGS |

| Effective working zone size | 224/4412/5512/5518 |

| Advantage | Long Service Life |

| Temperature control independently | ≤ ±5 ℃ (using Ferro Brand MTH Temperature Measuring), Provided By The User. Under Vacuum Sintering Conditions, Follow The Processes Listed In The Item 10 Final Acceptance At The Buyer’s Site. The Temperature Measuring Ring Will Be Placed On The Graphite Plate For Testing At 1350-1550°C. |

Applications:

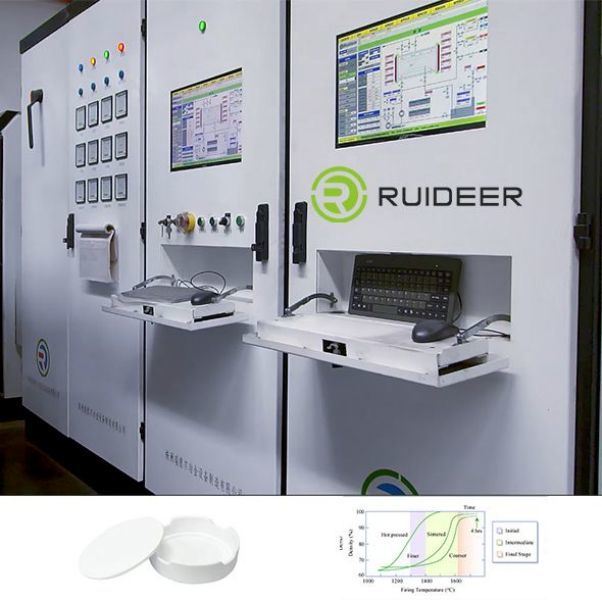

The RUIDEER Ceramic Sintering Furnace is a high-quality industrial furnace designed for ceramic sintering applications. With models available including 224, 4412, 5512, and 5518, this furnace is suitable for various load sizes ranging from 50 to 1500KGS, catering to a wide range of production needs.

Originating from China, this industrial furnace boasts a heating power of approximately 320KVA, ensuring efficient and reliable operation. It requires the buyer to provide a cable with a cross-section area of at least 185mm2 to support its functionalities.

Capable of reaching a maximum temperature of 2400℃, the RUIDEER Ceramic Sintering Furnace is ideal for high-temperature ceramic sintering processes. Its integrated design ensures seamless operation and precise temperature control, making it a versatile tool for various industrial scenarios.

With a dewaxing efficiency of at least 98% when using 10kg of Paraffin Refined Wax and employing Ar negative pressure dewaxing with three averages at most, this furnace guarantees high-quality sintering results for ceramic products.

Whether used in research laboratories, production facilities, or industrial workshops, the RUIDEER Ceramic Sintering Furnace excels in creating high-quality ceramic products with its advanced features and reliable performance. Its versatility and robust construction make it a valuable asset for any high-temperature industrial furnace application, especially in the realm of industrial ceramic sintering and high-temperature vacuum sintering processes.

Support and Services:

Our Ceramic Sintering Furnace product comes with comprehensive Product Technical Support and Services to ensure smooth operation and maintenance. Our team of experts is available to provide guidance on installation, troubleshooting, and optimization of the furnace. Additionally, we offer training programs to help users maximize the performance of the equipment. Our service team is committed to delivering prompt assistance and solutions to any issues that may arise, ensuring minimal downtime and continued productivity.

Packing and Shipping:

Product Packaging for Ceramic Sintering Furnace:

The Ceramic Sintering Furnace is carefully packaged in a sturdy cardboard box with ample protective padding to prevent any damage during transit. The furnace is securely placed in the center of the box to avoid any movement during shipping.

Shipping Information:

Once your order is processed, the Ceramic Sintering Furnace will be shipped via a reputable carrier such as UPS or FedEx. You will receive a tracking number to monitor the delivery status of your package. Please ensure someone is available to receive and sign for the delivery to ensure a safe arrival.

FAQ:

Q: What is the brand name of this Ceramic Sintering Furnace?

A: The brand name is RUIDEER.

Q: What are the available model numbers for this Ceramic Sintering Furnace?

A: The available model numbers are 224, 4412, 5512, and 5518.

Q: Where is this Ceramic Sintering Furnace manufactured?

A: This furnace is manufactured in China.

Q: What is the maximum temperature this Ceramic Sintering Furnace can reach?

A: The maximum temperature it can reach is [insert temperature here].

Q: Does this Ceramic Sintering Furnace come with a warranty?

A: [Insert warranty information here].

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!